500+ clients globally use Fruition's monday.com Consultants

Local monday.com consultants for Manufacturing in Australia, United States, and United Kingdom

Why Manufacturing Teams are Implementing monday.com

01

Process Management

📅

Production Planning: Streamline manufacturing logistics with efficient scheduling and management tools

✅

Quality Control: Implement robust quality assurance workflows that ensure consistent product excellence

📦

Inventory Management: Track stock levels precisely and automate replenishment to prevent stockouts

02

Resource Optimization

🗂️

Resource Allocation: Maximise efficiency with smart resource distribution across production lines

🔄

Supplier Coordination: Manage vendor relationships and track material deliveries and procurement seamlessly

✏️

Health & Safety: Maintain compliance with built-in OHS regulation tracking features

03

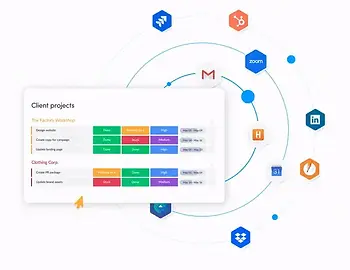

Technology Integration

✅

System Integration: Connect smoothly with your existing ERP and MES software ecosystem

📋

Automation Capabilities: Reduce manual tasks through intelligent process automation

📁

Custom Analytics: Generate insightful reports with manufacturing-specific metrics

04

Team Collaboration

⚖️

Intuitive Interface: Enable quick team adoption through monday.com's user-friendly design

🔧

Real-time Communication: Keep all stakeholders and vendors connected and informed throughout production cycles

📍

Visual Dashboards: Monitor key performance indicators through customizable visual displays

Schedule a 30 minute Call with a monday.com Expert Today!

From initial process discovery to full system adoption for your monday.com manufacturing solution for project management, our proven methodology ensures seamless digital transformation that empowers your team and drives sustainable operational efficiency.

Frequently asked questions